How 3D Printing Works: From Digital Dreams to Solid Reality

- Aug 2

- 4 min read

Welcome to the Magic of 3D Printing (No Wizards Required)

Ever wished you could just snap your fingers and make something appear out of thin air? Well, science isn’t quite there yet but 3D printing is the next best thing. It’s like having a futuristic vending machine but instead of spitting out chips and soda, it creates literally anything you can dream up - phone cases, prosthetic limbs, a tiny army of plastic dinosaurs (because why not?) Pssst, want to take a look at some of these cool stuff? Here's a link to All Products in stock now (Use coupon code ATHENA10 for a discount, yayy)

But how does this wizardry actually work? Let’s break it down - no PhD required, just a little curiosity and maybe a cup of coffee!

Step 1: The Digital Blueprint (A.K.A. "The Master Plan")

Everything starts with an idea. But instead of sketching it on a napkin (or the back of your hand), 3D printing requires a digital model.

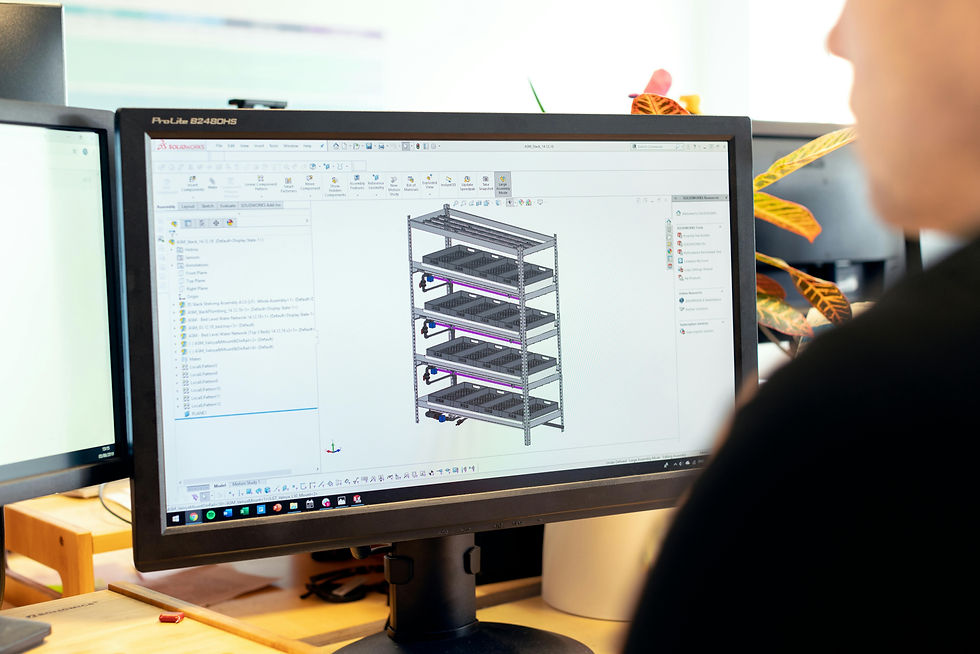

This is usually made using CAD software (think AutoCAD, Fusion 360 or Blender). If designing isn’t your thing, don’t worry - you can also download pre-made 3D models from many sites out there.

Once the model is ready, it needs to be converted into a printable format, usually an STL (Standard Triangle Language) file.

This file is basically a fancy way of saying, “Hey printer, here’s what I want - make it happen.”

Step 2: Slicing and Dicing (No Knives Involved)

Before your printer can get to work, it needs some instructions. This is where slicing software (like Cura or PrusaSlicer) comes in. Think of it as Google Maps for your printer - it tells the machine exactly how to build your object layer by layer.

Slicing software does a few cool things:

Converts the model into G-code (the machine’s language)

Decides layer height (finer layers = smoother prints, but longer wait times)

Generates supports (for overhangs that would otherwise print in midair like a rebellious teenager)

Once the file is sliced, it’s ready to roll!

Step 3: Printing Begins (Cue the Suspenseful Music)

Now, the real action begins. The printer takes the G-code instructions and starts building your object layer by layer.

There are different types of 3D printing technologies but the most common one (and the one your friendly neighborhood hobbyist probably uses) is FDM (Fused Deposition Modeling).

How FDM Works:

Filament Feeds In – A spool of plastic filament (usually PLA, ABS or PETG) is heated until it melts.

Extrusion Magic – The melted plastic is pushed through a nozzle and deposited onto the print bed.

Layer by Layer Construction – As each layer cools, the next one is added on top, slowly building your object from the ground up.

The Waiting Game – Prints can take anywhere from minutes to hours (or even days if you’re ambitious). This is a great time to make a snack, binge a show or question all your life choices.

Other printing methods like SLA (Stereolithography) and SLS (Selective Laser Sintering) use lasers and resin instead of melted plastic, but we’ll save those for another blog post. Check out Athena Craftwork's Instagram to see all of these in action!!

Step 4: The Grand Reveal (And Maybe Some Sanding)

Once the print is done, you can finally admire your creation! But wait, sometimes prints don’t come out perfect.

That’s where post-processing comes in:

Removing supports – Unless you want your print looking like it walked out of a spider web.

Sanding – To smooth out any layer lines and give it that sleek, professional finish.

Painting or Polishing – Because sometimes raw plastic just isn’t fancy enough.

Why Should You Care About 3D Printing?

Because it’s awesome!

But beyond that:

Endless Customization – No more settling for mass-produced junk.

Cost Savings – Print spare parts, tools, or gifts without breaking the bank.

Eco-Friendly Options – Many filaments are biodegradable or made from recycled materials.

Pure Fun – Let’s be honest, watching something appear out of thin air is just cool.

Explore the World of 3D Printing with Athena Craftworks

At Athena Craftworks, we don’t just use 3D printing - we master it. Whether it’s creating custom Hot Wheels displays, elegant lightboxes or engineering-grade prototypes, we combine precision and grace to craft something special every time.

Come explore our collection and see what’s possible with the magic of 3D printing. Whether you're a collector, creator or just curious about this incredible technology, we've got something for you🚀

Comments